Reference Film originates from ASTM Standards, which refers to as the standard material that is used for the unification and standardization of gas permeability tests with various methods. In accordance with the requirements of NIST (the National Institute of Standard and Technology), both polycarbonate (PC) and polyethylene phthalate polymers (PET) can be used as materials that ensure the stability and uniformity of the reference films. The Reference Film for Gas permeability Test of Labthink has been approved by State Administration for Quality Supervision and Inspection and Quarantine of the People’s Republic of China (AQSIQ) and registered as Scientific and Technological Achievement.

Specifications

The thickness of the reference film should be uniform. In accordance with GB/T 6672, at least 5 points in the specimen should be measured. The average value can be calculated with the recorded maximum and minimum values. The thickness of the reference film is indicated in the Certification of Reference Film. Reference film should be homogeneous and free of impurity and conform to the requirements of NISTThe reference film should be representative and free of any folds, creases, pinholes, contaminations or other uncertain defects

Functional Requirements for Package

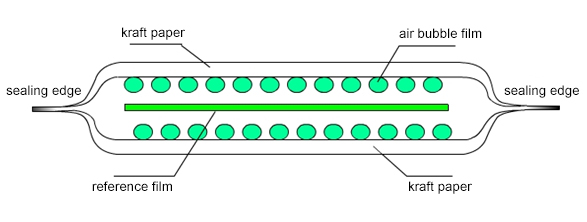

The reference film is packed in the package shown in the following picture. It's waterproof, crushproof, lightproof and wrinkleproof, so that reliable transportation and storage as well as easy opening can be guaranteed. At the same time, the package is recyclable and environmental friendly.

Sectional Drawing of the Package for Reference Film

The outermost layer is used to prevent the package from water and moisture. Moreover, it is used to protect the inner paper layer which may be easily brokenKraft or other paper materials are suitable for printingExternal crashing and squeezing can be greatly reduced by the inflatable air cushion layer bond to the paper layer The whole package is completed by heat sealingExternal Packaging Design

Test before delivery

In order to be more objective and scientific, the reference film is required to be tested before it is delivered to the customer. The corresponding testing procedures are as follows:

Appearance inspection → Sampling → Conditioning of the specimen → Mounting the Specimen (Scratch or contamination should be avoided) → Testing → Filling in the information of the corresponding reference film on the package → Filling in the testing data, thickness and other parameters in the certificate of the reference film → prepare related documentation of the reference film

Available models

Low and medium barrier property materials----

- Reference film—RF-CNCA-07-A03-1

- Reference film—RF-CNCA-07-A03-2

- Reference film—RF-CNCA-07-A03-3

Packing List

Reference Film and Reference Documentations

Note: The minimum order quantity of the reference film is one piece.

After testing, gently remove the reference film from testing chamberUsing degreased cotton to clean the sealing grease remained on the film surface. Handle with care to avoid damages to the reference film.Placing the reference film between two pieces of filter papers and place them into drying vessel for 24 hoursPacking and sealing the reference film in plastic packaging for preservation in a standard laboratory condition. When repeating the operation, follow the Testing Procedures of Reference Film in the reference documentations.Validity period: 6 months